CAD and Computer Analysis

Get CAD models that can be used for prototyping and manufacturing

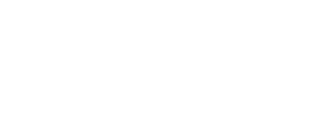

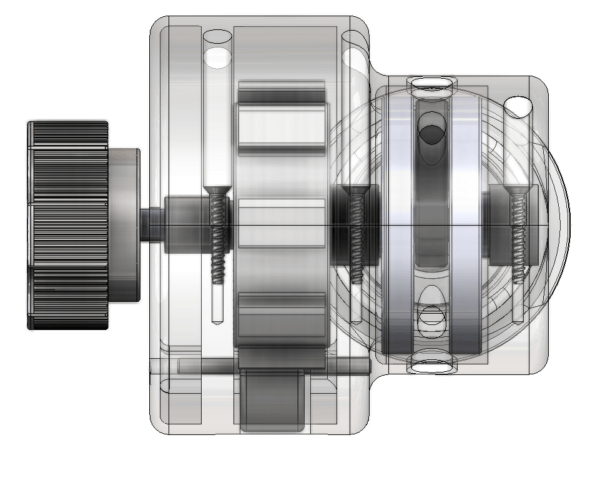

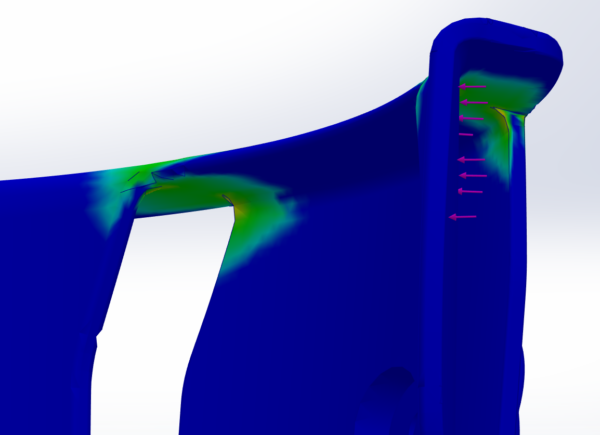

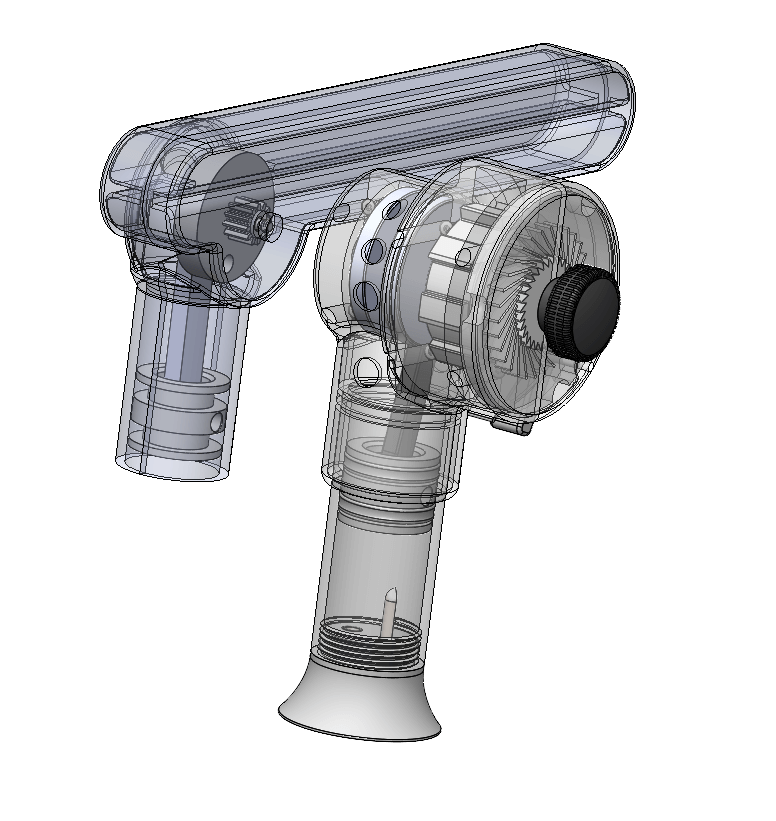

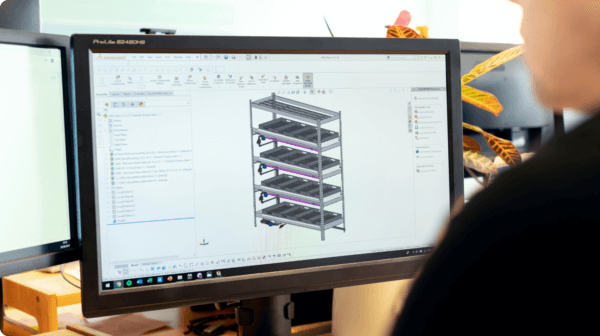

3D Modeling allows you to design and then view different concepts and features of your product before you build a prototype, and decide what would work best for your product. Computer Simulation allows Kickr Engineers to use advanced computer programs to look at fluid flow or forces on parts of your product to help optimize the design in a digital environment.

We do things differently

Whether you need CAD models and drawings for 3D printing, manufacturing, visual rendering, simulation or more, our engineers and CAD experts can create optimized CAD files for injection molding, machining, prototyping and manufacturing.

How our engineers can help

Innovations we’ve been part of

Let’s bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Fill out the form for your free cost estimate.

"*" indicates required fields