Quick Tourniquet Innovation

The Client

As an army reservist, our client Nathan learned how to use a tourniquet to prevent blood loss from wounds sustained in battle. During training, he was surprised at how difficult it was to apply a tourniquet effectively. This issue resonated with Nathan in particular because he had lost his family in battle from wound complications and blood loss, something he felt could have been prevented. After learning that tourniquet designs have not been updated for over 100 years, he decided that his fellow soldiers deserve a better solution to rely on when their lives are on the line.

The Challenge

Nathan had a clear concept for his design, but did not have the product development and engineering resources on his own to build a reliable prototype for testing and evaluation. He was very experienced with the challenge he was trying to solve, and he needed a product engineering company that would be able to incorporate his own ideas throughout the product development process. He also needed to keep his production costs low so he could successfully scale his manufacturing to meet the needs of the military. During his project outline & estimate discussions with us, he revealed two main pain-points that the current tourniquet solution presents:

- Tourniquets take too long to apply in a life-threatening situation

- Tourniquets inflict serious pain when used correctly, causing users to leave them loose

The Solution

Kickr Design met with Nathan, learned about his project, and provided him with a Free Project Outline & Estimate that highlighted a combination of industrial design, engineering, and prototyping services to help him achieve his project goals. With a clear path forward, we designed & built a fully functional prototype and delivered it to him so he could test it and evaluate with the military. The prototype was built and delivered within his budget, and he was able to minimize his manufacturing costs for future production.

The Development Process

Highlights from this project:

Snap On Bracelet Inspiration

Our client wanted to incorporate a snap-on feature into his new Quick Tourniquet

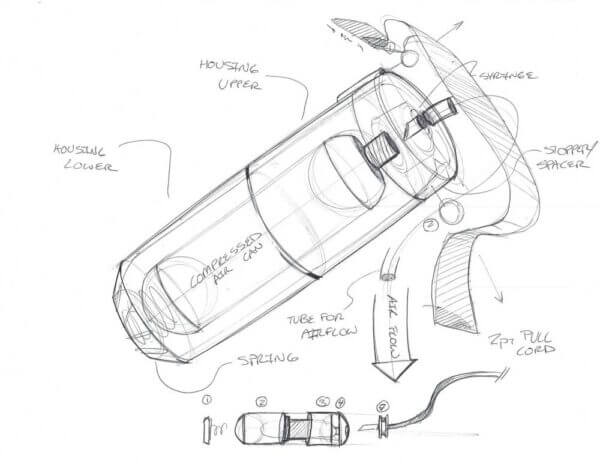

Concept Sketches – Wristband

Design drawings presented to the client that incorporated the snap on concept

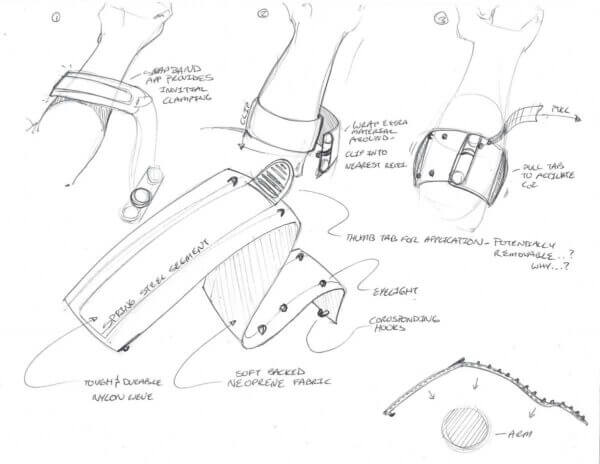

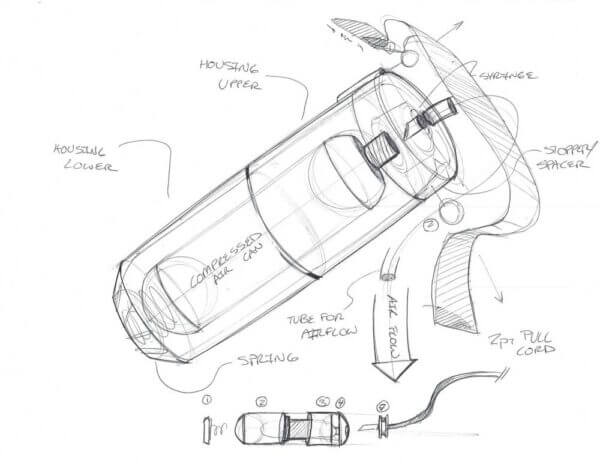

Concept Sketches – Custom Pneumatic Mechanism

To apply enough pressure in an instant, our client chose to use off-the-shelf CO2 components

Custom Machined Prototype

Evolution of Clip – CAD

The attachment clip was optimized for reliability and ease of use through 4 fast iterations (from L to R)

Product Rendering

Final prototype of the design holding the putter upright

Initial Delivered Prototype

A fully functioning prototype that is used to test and evaluate the different features and concepts of the Quick Tourniquet

The Results

Through internal testing, Nathan found that his new Quick Tourniquet solution was easier to apply, reducing the need for expensive training courses. And it is faster to apply— just 7 seconds vs the 60 seconds it takes with a conventional tourniquet. His new design also applies uniform pressure around the circumference of the affected limb, relieving the pain experienced when tightening a tourniquet by hand. Nathan has successfully pitched his prototype and we are now working with him to manufacture his new product at scale for distribution.