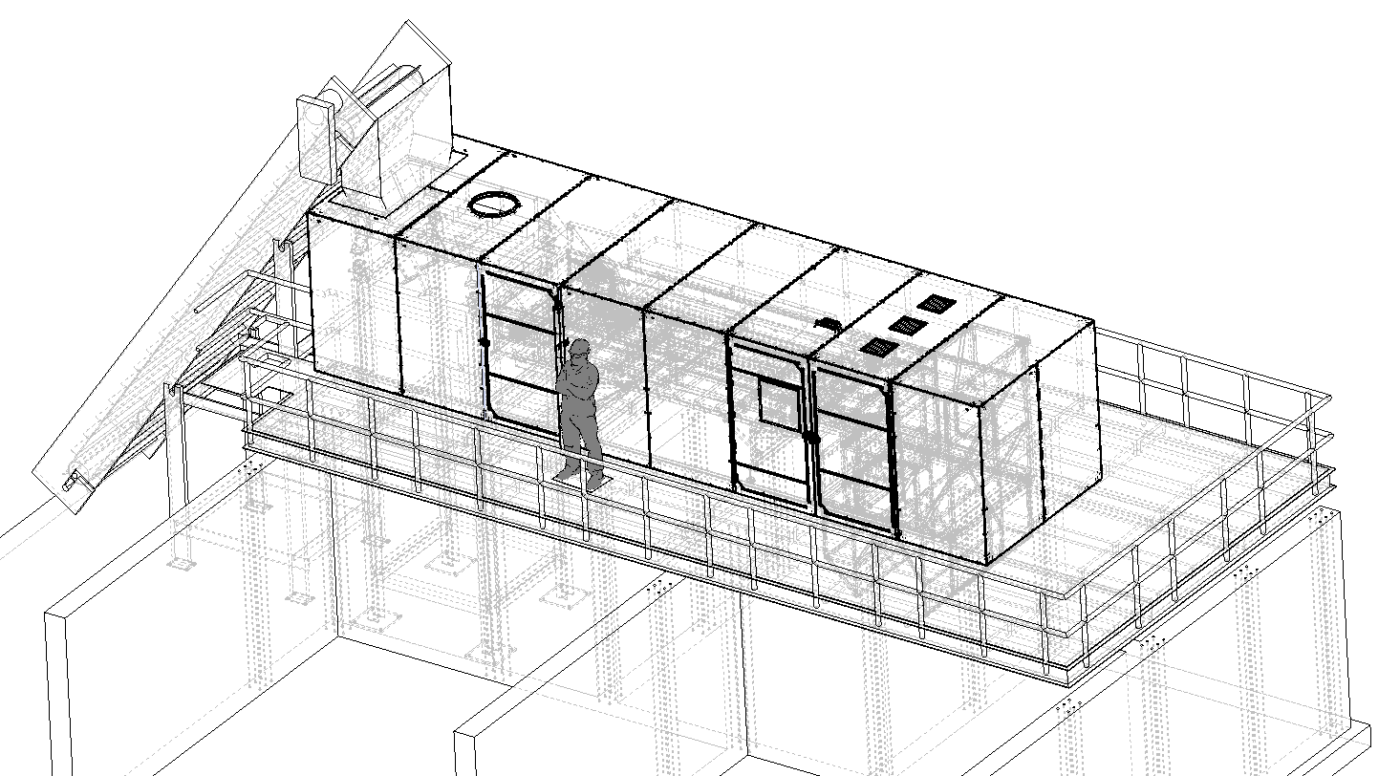

Industrial equipment and Factory Automation

Your R&D partner for creating new equipment tailored to your exacting needs

Our approach to industrial equipment systems design

First, we listen. As a good partner, we want to know exactly what is needed in your process, concept ideas, system, and business goals you want to achieve with your new equipment.

Second, we create a plan. A scope of work is created based on our mutual understanding and your budgetary planning. Plans can (and should be!) flexible in any new R&D or Equipment Engineering project. Being sensitive to new opportunities we may discover together enables us to pivot when you need us to pivot.

Third, we design. This is the exciting part! A team of multidisciplinary engineers is assigned to your project and meets with your team to discuss equipment design concepts. We leverage our professional design engineering experience to make key decisions toward an effective outcome. This is an iterative and highly collaborative process between you and Kickr Design.

The finished result is a fully operational pilot or production equipment for your team to test in your facility’s industrial process.

What do we consider when designing new process equipment?

Many aspects need to be considered when designing new automated processes or production equipment. Here at Kickr Design, we leverage our experience across multiple industries including solar and battery manufacturing, electronics manufacturing, recycling and sorting, and roll equipment among others to innovate, design and build you the most effective equipment for your process. Below are some considerations we look at when designing new factory equipment:

- Feed requirements – types of loads, their orientation, conveyance types and speeds.

- Automation peripherals – sorting systems, complete robotic or partial human handling.

- Programmable Logic Controllers – applied scale is key to knowing the right PLC for the job.

- Industrial design – human factors engineering, human-machine interface and safety, and branding aesthetics.

- Installation design – how the new prototype is transported to and installed at your facility.

- Testing and training – once the new equipment is installed we test it and train your staff.

- Maintenance – How will your staff perform upkeep and maintenance on the equipment? We factor in planned maintenance schedules based on your needs.

How can Kickr help?

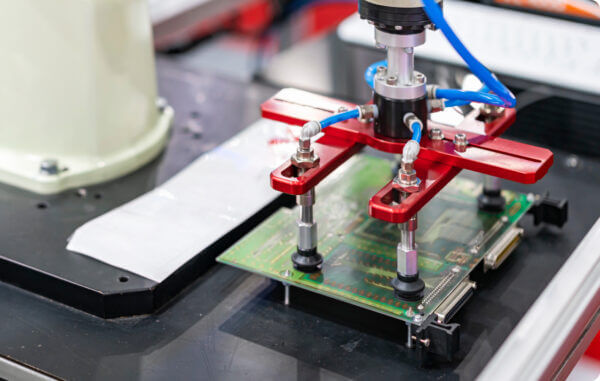

Control systems are the brains of your industrial equipment – providing the automation, operator interfaces and system controls to ensure smooth and reliable equipment operation. Whether you need help with just control systems, PLC programming or power electronics, our engineering team can fit in to assist wherever you need assistance.

Leveraging our experience with Allen Bradley safetyLogix safety PLCs and intelligent machine enclosure design, we can help design, fabricate and install machine safety systems in your facility.be sure the new equipment is designed to either enhance or meet

current ISO or other QA protocols for your industry.

Once the equipment is compete, the final step prior to full operation is process development. Whether you have in-house process development resources or not, Kickr process engineers can assist in setting up thoughtful DofE (Design of Experiments) and data collection systems to evaluate the efficacy of the process and equipment, analyze the data using statistical software such as Minitab to tease out complex variables and understand what knobs to adjust to optimize throughput and product quality.

Kickr can help evaluate your current process and equipment and look for areas where we can improve the current process and equipment. This could include adding validation systems and vision, adding additional automation controls or adjusting the current mechanical systems for increased throughput and effectiveness. Part of our value is being able to leverage our team’s broad base in solutions and pull ideas from across industries to help you improve your factory or equipment efficiency.

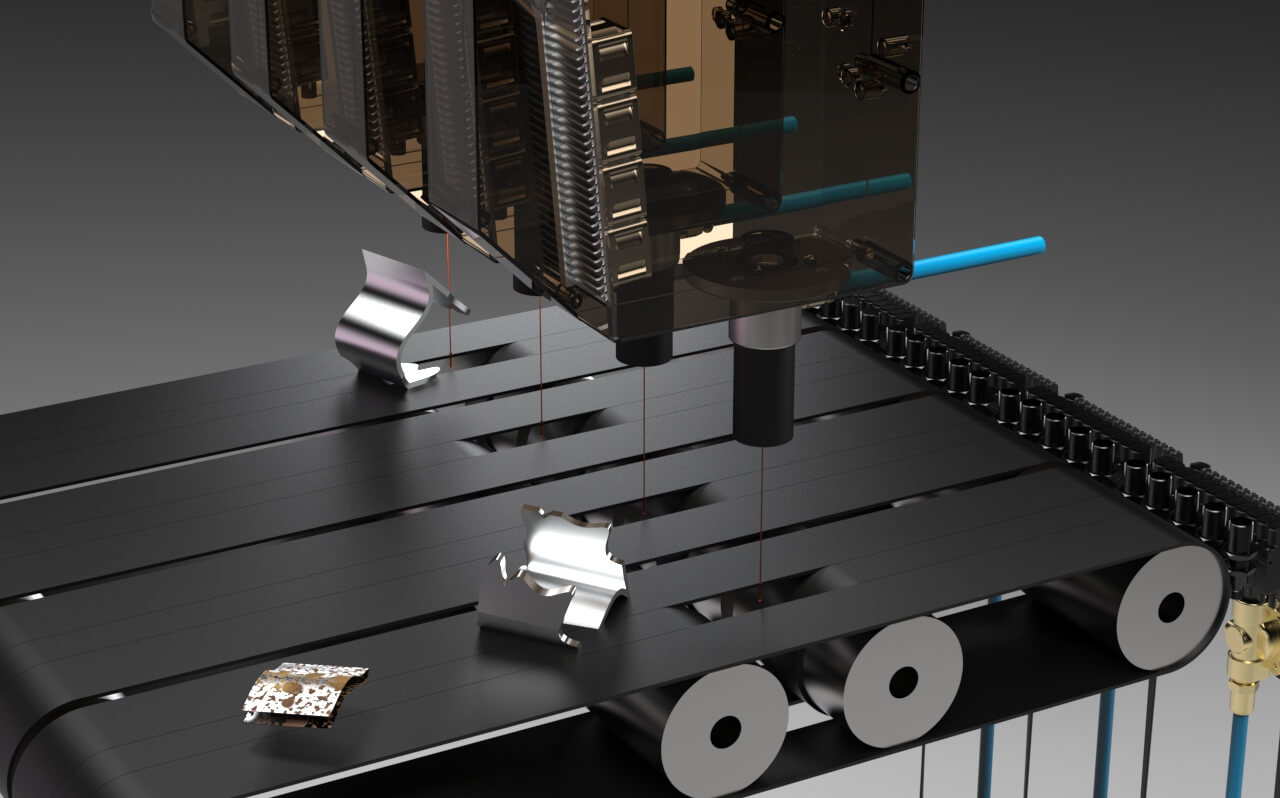

Metal Sorting Machine

Our team was approached by an aluminum manufacturer to help them identify, design, develop and assist with the installation of a laser-powered metal alloy sorter in their manufacturing facility.

Industrial equipment projects we’ve been part of

Let’s bring your project to life!

Our team of engineers is here to help. We offer free consultations and estimates.

Fill out the form for your free cost estimate.

"*" indicates required fields