Not a one-size-fits-all process

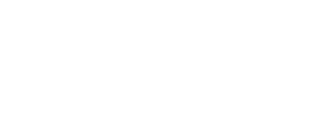

Our superpower is building a development pathway that matches your needs.

Think of us as an extension of you and your team, providing the right engineering and design resources at just the right time. It starts with making sure we deeply understand your needs, goals, and capabilities so we can leverage specific expertise from our team to complement you and your project’s needs.

Our approach to your engineering, design and process challenges

Every product and project is unique, as is every company and inventor. We recognize those differences and don’t settle for a one-size-fits-all approach. We create a custom development plan for every project, incorporating the right mix of design, R&D, engineering, prototyping, and manufacturing for your exact needs.

Explore different ways we tackle projects below:

When a product is high complexity, or has exceptionally rigorous process and testing requirements, we must adjust our approach to ensure we cover all critical aspects of not just the technical development, but also the documentation, testing to specific standards and in-depth risk analysis both overall and per component. Below is an example of a development process we designed for one of our customers’ complex medical device products.

Developing consumer products requires a strong foundation and understanding of the end customer and the problem you are helping them solve. Its not enough to just think about the technical solution, but how the user will see the product on the shelf, understand it’s purpose and interact with it during use. Matching a competent technical solution to great product design fundamentals is what we do here at Kickr Design. Below is an example of a development process for one of our customer’s products.

Developing custom industrial automated equipment requires a careful approach to ensure success. Building an initial pilot tool that has the necessary adjustability to accommodate for process development and process adjustment, while minimizing over-engineering and ensuring that the ultimate machine cost and feature-set match the production needs is not trivial, but achievable. In Kickr’s Industrial Automation development process, we take care to correctly gather the key information up-front and evaluate feature risk along the way. Below is an example of a process we took with one of our customers when developing a large production-level automated machine.

R&D is often an early stage, blue sky evaluation of a problem and solution space. We work with our customers to define the parameters of the solutions we are searching for, and closely monitor our progress with our client to ensure that we stay on-track and on-budget given their R&D goals. Below is an example of a process we took with one of our R&D clients after taking the time to understand their R&D goals..

Let’s bring your project to life!

You bring the vision, we’ll bring the resources to help you build it!

We are always happy to walk you through all your options and help you make informed decisions throughout your product development journey. We know timelines, goals and needs can even change during a project, and pride ourselves on our deep understanding and real-time flexibility to pivot with you when necessary.

Fill out the form for your free cost estimate.

"*" indicates required fields