Greenzie

The Client

Charles Brian Quinn (CBQ), CEO of Greenzie (www.greenzie.com), is revolutionizing outdoor robotics, and starting with the green industry. The Greenzie software and retrofit kit for commercial lawn mowers adds robotics to existing equipment making them autonomous. His sophisticated software is able to gather data about a particular lawn and map out an optimized path for mowing! He and his team successfully tested and refined their software using a small “off-the-shelf” robot that did not include lawn mowing capabilities. But, in order to further develop their product and continue fundraising, the Greenzie team needed to perform field tests with a real lawn mower and show off its true ingenuity. The only problem was… such a lawnmower didn’t exist at the time!

The Challenge

CBQ and the Greenzie team wanted to demonstrate the full capability of their product by controlling a real, functioning, commercial lawn mower with their software. That way, their test results would be more helpful and potential investors could easily grasp their concept. Because Greenzie was in startup mode, moving quick and with only one Full-Time Engineer on staff at the time, they needed to find a company that was capable of delivering such a prototype in time for their live demo day.

The Solution

CBQ met with a lead engineer to help identify what services he needed, and which ones he did not. We came up with a plan to deliver him a fully functional lawnmower prototype so that he could use it to show off his software system. Here’s what we were able to do for him:

-Delivered a fully functioning lawnmower prototype in just over 3 months

-We modified the lawnmower’s mechanical controls and added servo motors to reliably power the updated mechanism

-The new motors can be easily controlled by Greenzie’s software outputs

-All of the modifications and new parts are concealed within other parts of the mower, and the mower can still be used in manual mode if needed

The Development Process

Highlights from this project:

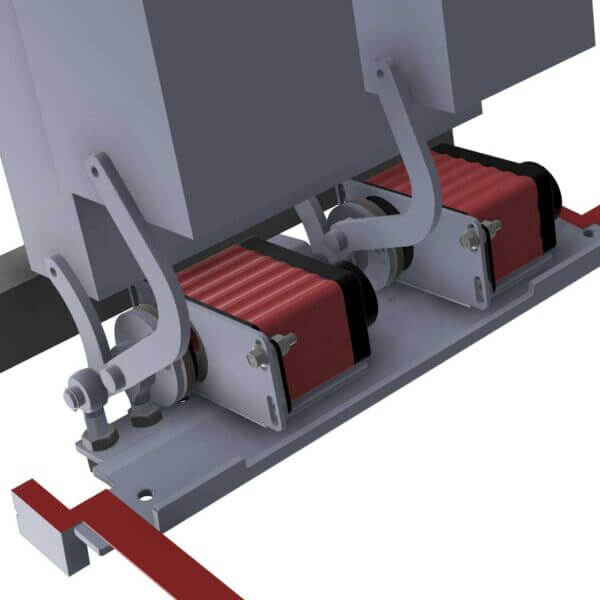

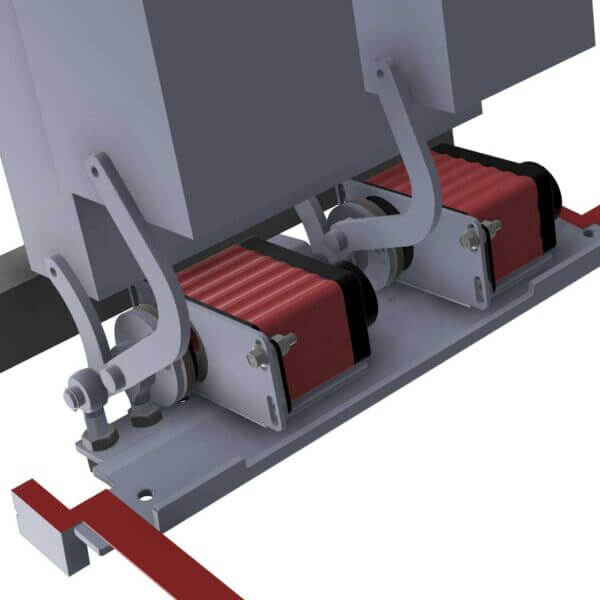

Designing the Motorized Mechanism with CAD

Includes servo motors and custom linkages to tap into the existing lawnmower controls

We Needed More Room for Motors, So We Made Some

Modifying the existing lawnmower part to accommodate the new motors

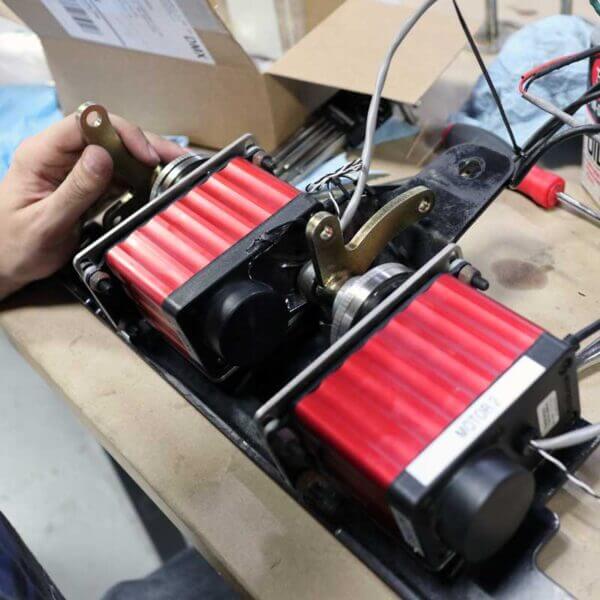

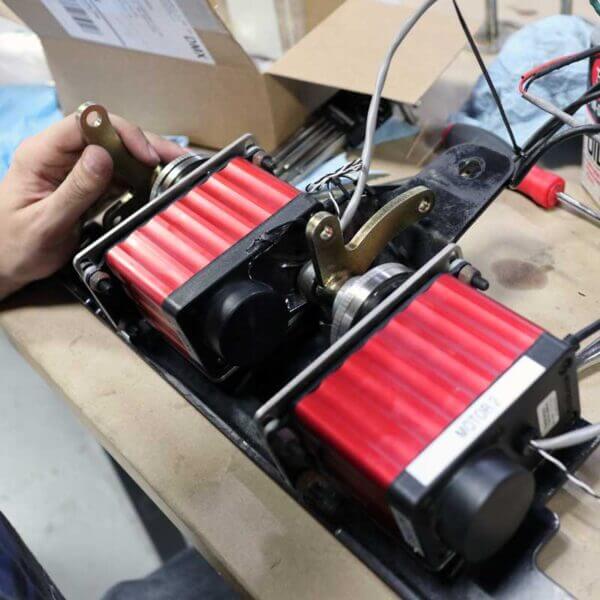

Assembling the New Mechanism by Hand

Putting together the motors, brackets, and linkages for the control mechanism

Prototype Delivered to CBQ

Excited to deploy his new robotic lawnmower and start saving on labor costs

The Results

CBQ was delighted to receive his lawnmower prototype in plenty of time for his demo day. The prototype was used to demonstrate their software in a live field test to investors and potential customers. Greenzie successfully raised over $500K to continue developing their product as a result of a successful demonstration. They accomplished all of this without having to hire and build a large hardware team, saving them time and money. As they continue to discover new opportunities for their product, we look forward to providing more on-demand engineering services when needed. You can request to try their automated lawn mowing service at www.greenzie.com or check out their demo day experience here.

Love love love working with Kickr Design. Their expertise and knowledge of product design, engineering, and rapid prototyping as a team is solid… A++ would work with again and continue to use them!”

CBQ, CEO of Greenzie