Product and market studies reveal that material selection is deeply embedded in product design, as the substance embodies the vision and intention behind the design. Additionally, strategic use of materials is one of the most effective ways to enhance the user experience and for product creators to cultivate a deeper connection between end-users and their products.[1]

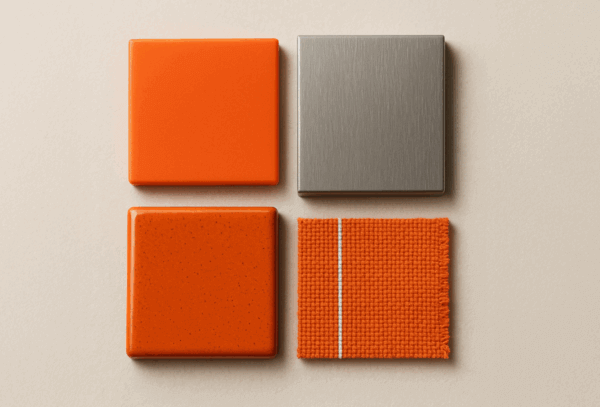

The right material will affect not only user experience, product use, and function, but also durability, compliance, and production cost. The type of product being developed should immediately indicate the appropriate category, hard goods or soft goods, or whether a hybrid solution is necessary.

Product Performance: Considerations For Material Selection

- Functionality: The material selection must adequately match the product’s intended use. Consider the need for elasticity, strength, corrosion resistance, temperature resistance, insulation, and more.

- User Experience: End-users should find the material comfortable and safe, considering aspects like skin sensitivity, heat transfer, and ergonomic fit.

- Durability: Select a material that suits the longest possible product lifecycle, considering the operating conditions in which it will be used and the frequency of use.

- Regulatory Compliance: Materials must align with any relevant regulatory compliance requirements established by the industry for safety.

- Production Cost: Cost-effective material section must meet the product’s performance requirements without compromising quality.

- Aesthetics: Appearance, texture, color, and finish are all aspects of product aesthetics that will be influenced by material selection.

- Environmental Impact: For sustainable or eco-friendly products and brands, materials that are recyclable, have a reduced carbon footprint, or decrease ecological impact should be at the top of the list.

- Manufacturing Process Compatibility: The material choice will determine, in part, what production options are available for product development and mass manufacturing. Some methods include injection molding, CNC machining, or 3D printing, which only work with certain materials.

Learn more about how to choose the best materials for your product here.

Hard Goods vs Soft Goods & How They Perform

Hard goods are firm, rigid materials, such as plastic, wood, or metal, whereas soft goods are flexible or textile materials, including foam, leather, or Kevlar.

Plastics

This category encompasses soft, pliable plastics, as well as weather-resistant or rugged plastics, and 3D-printed plastic components. Each type will vary in performance in terms of strength, flexibility, chemical composition, resistance, transparency, stability, and cost, offering nearly endless opportunities for implementation.

Metals

Common metals used in product development may include stainless steel, aluminum, medical-grade titanium, copper, brass, zinc, magnesium, and others. Each metal is characterized by distinct performance properties, including density, weight, strength, cost, corrosion resistance, and heat resistance, each with a unique set of applications.

Woods

Aesthetics, durability, stability, cost, and ease of use are some of the primary factors that influence product designs involving wood components. Hardwoods like oak and walnut are suitable for vastly different products than those that would perform well with soft MDF composites or pine.

Ceramics

Traditional or engineered ceramic materials like cordierite, steatite, silicone carbide or nitride, and aluminium oxide may offer superior electrical or thermal properties that enable performance in environments or applications where other materials would fail. Each would perform differently in terms of strength, weight, temperature resistance, cost, and electrical properties.

Composites

Composite materials are made from two or more distinct materials to create something new. Examples of composite materials include concrete, carbon fiber, fiberglass, and carbon fiber-reinforced polymer. Products made from composite materials exhibit distinct performance characteristics, which could include a high strength-to-weight ratio, corrosion resistance, reduced weight or density, and thermal insulation.

Textiles

Textiles encompass a wide range of fiber types, including both natural and synthetic materials, such as cotton, silk, polyester, nylon, wool, linen, and rayon, among others. Each textile would perform slightly differently, depending on the product’s intended use. Examples include Kevlar for protective gear or industrial materials for filtration.

Flexible Materials

Flexible materials commonly used in product development are rubber, silicone, thermoplastics, and polyimide. The distinct performance properties of flexible materials include elasticity, chemical resistance, various printing methods, and temperature resistance.

Learn more about soft goods vs hard goods in product design here.

If you need help with material selection, product design, preparing for production, or regulatory compliance, connect with our team here, and we can help you come up with a plan.

Sources: