The Client

Chris is a co-founder & the CEO of VRgluv, a startup that builds high-tech haptic gloves for virtual reality. Chris and his team built many successful prototypes made from 3D prints & breadboard electronics to prove their concept and seek funding for their new company. Their prototypes worked great, but Chris knew that he would have to bring in some electrical engineering expertise to turn his breadboards into smaller, reproducible PCBs for manufacturing. After weeks of interviewing some electrical engineers, Chris realized he would have to hire three engineers with different specialties to get his PCBs developed. This would cost him $150,000 in salaries plus benefits in six short months, and Chris had no other project for them to keep them busy after that.

The Challenge

-Needed to find electrical engineers who can start working immediately and stop working when the project is completed

-Required an electrical team that can transform his prototypes into reproducible PCBs to put in the final product

-Needed to stop spending time on HR and refocus on developing his product

-Looked to significantly reduce the cost of hiring an engineering team

The Solution

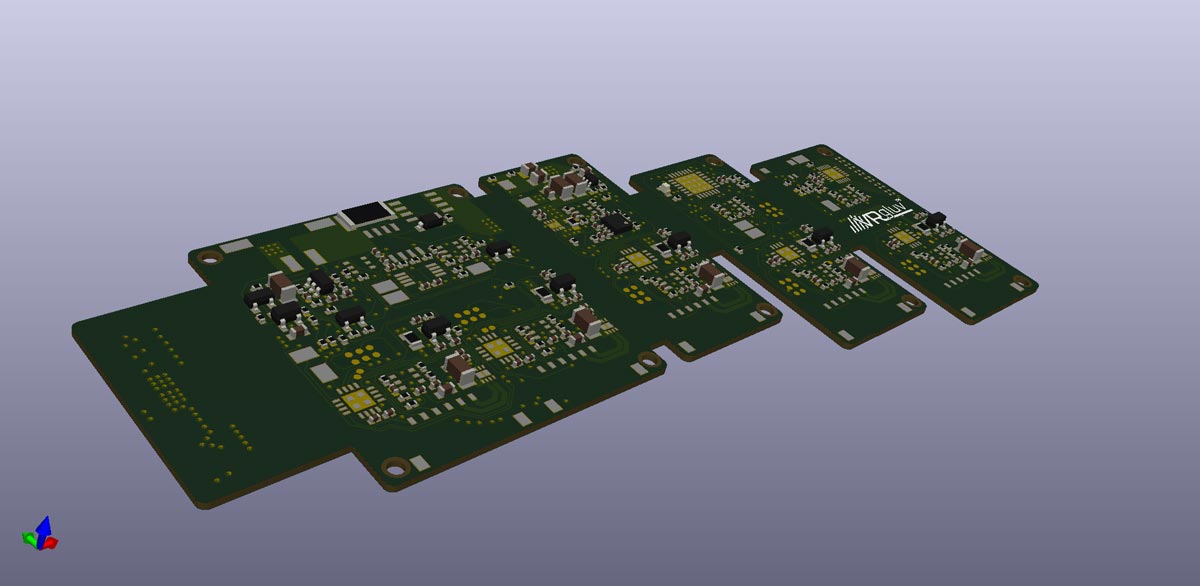

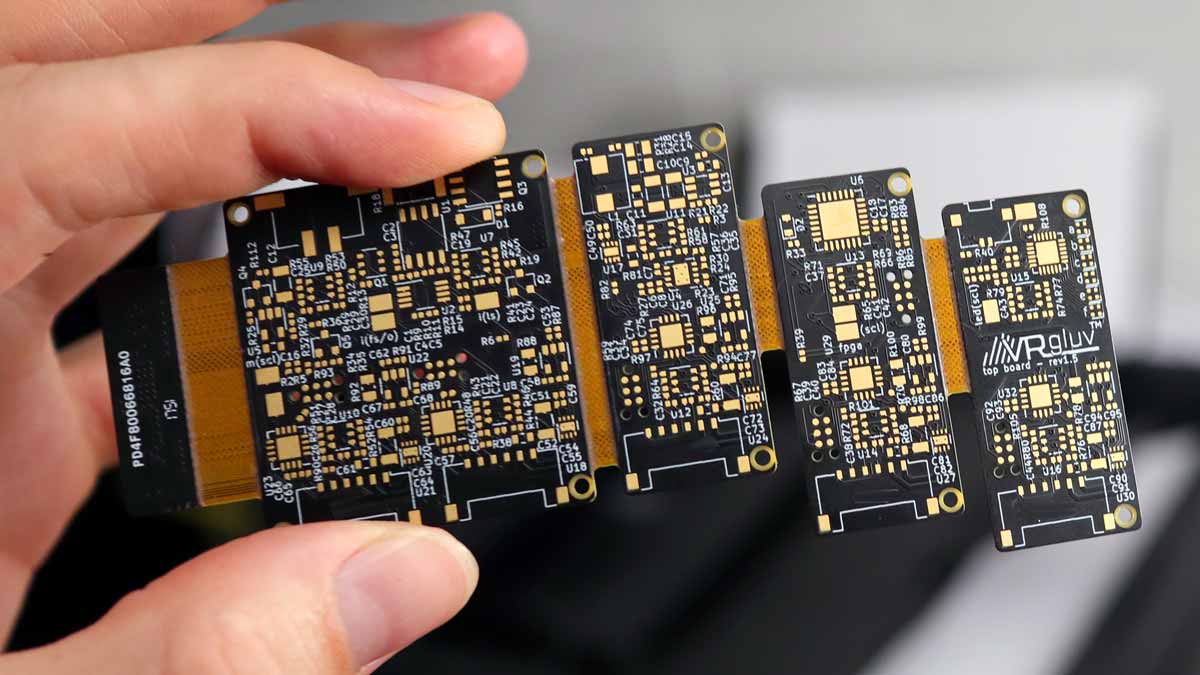

Chris met with a lead engineer at Kickr Design, and we learned about his current challenges so we could build him a plan that would work for his specific needs that included PCB design, fabrication, firmware, and testing. We also structured a payment plan that would work on his terms, and that he could adjust at any time. After finalizing his path forward, Chris immediately deployed one of our electrical engineers to design a PCB, then added 2 more engineers when he needed to produce and program the boards. When it was time to test the boards, Chris scaled back to just 1 firmware engineer to finish out the project. We produced and delivered a dozen PCBs to Chris' specification in 4 months that are currently being used in the latest version of his product.

The Results

Chris saved both time and money on his project by working with us rather than building out his own engineering team. He was able to scale his engineering capacity when he needed to, both up and down, and he only paid for the engineering time actually spent working on his project. Chris completed his project faster by working with us because he was able to deploy engineers immediately and didn't have to spend weeks finding and building his own team. Overall, Chris saved an estimated 2 months of development time and saved over 75% on the cost of development for his PCBs compared to finding, hiring, and paying for his own internal engineering team.

Project Gallery

If you need an engineer to help develop your hardware product, talk to an engineer and get a Free Project Outline & Estimate.